Tyres are the only point of contact between the bike and the ground, so the safety and performance rider and bike’s depends on the small surface of their footprint.

The wrong choice can render useless the extraordinary technological expertise of the most advanced bike, ruin an excellent training session or turn that long ride you've been planning into a nightmare. That's why it's so important to choose your tyres wisely.

Image: © Specialized Bicycles

Image: © Specialized Bicycles

The qualities or performance to look for in a road tyre are:

- Low rolling resistance

- Low weight

- Grip and braking retention

- Puncture resistance

- Ride comfort

It seems impossible to achieve all this in such a small area, especially when some of these features are to the detriment of others. But the great technology behind them makes it possible to achieve features that were unthinkable not so long ago. It is usually best to find a balance, depending on your needs and, fortunately, the sector offers an extraordinary range of products to help make the right choice.

It is a question of identifying your needs and looking for the product that comes closest to this balance. Here, we will look at the most important factors to ensure the correct choice of a road tyre .

1. Types of Road Tyres

There are four types of road tyres and we will look at the pros and cons, as well as their best areas of use.

1.1 Tyre with Inner Tube

Currently the most popular tyre among road cyclists, it consists of a U-shaped tyre with a reinforced edge or bead. The bead fits into the rim of the wheel, thanks to the air pressure of the inner tube.

The tyre consists of an inner casing and the tread or outer layer which is in contact with the ground.

Medium and high quality tyres also include a puncture protection strip between the casing and the tread.

The reinforced bead of the tyre is usually a rigid steel wire or flexible kevlar ring. Steel beads are found in the simplest, most affordable ranges, but they are also the heaviest. Kevlar beads are lighter and the tyres can be folded, but they have a higher price.

Pros: This type of tyre has gained in popularity because of the affordable price in the entry-level ranges and, above all, because it is

easy to fit and repair. It is also much easier to carry spares for repairing a puncture: spare inner tubes, patches and tyre levers are sufficient for repair in most cases.

Cons: This system is the most exposed to punctures out of the four types available, although the new compounds mentioned in section 1.3 Composition are minimising this. And, with respect to its rival, the Tubular, the maximum pressure they admit is much lower, so they cannot match low rolling resistance figures. However, high pressure is only definitive for competition and, as we will see later, the development of conventional tyres means they now come very close to the performance of tubulars without their major drawbacks.

Recommended use: Due to the wide variety and range of use, this is the most versatile option for road cycling and recommended for the majority of cyclists, together with the tubeless version that we will see below.

1.2 Tubeless Tyres

The tubeless system dispenses with the inner tube and the airtight seal is achieved by the tyre itself, thanks to its inner liner and reinforced sidewall. It is important that the wheel rims are airtight, which means either purchasing airtight rims or, adapting them by means of a tubeless kit. Despite the overwhelming success of these tyres for MTB use, road cyclists have been very reluctant to to use them, although they are gradually becoming more popular, due to the reasons below.

Pros: Punctures are drastically reduced for two reasons. There is no inner tube and, the use of liquid sealant repairs the most common small punctures. The absence of the inner tube and the reinforced walls allows lower air pressure, which improves safety and riding comfort, especially on uneven or wet roads.

Disadvantages: Some tubeless tyres are difficult to fit, which can be difficult if you get a puncture on the road, or a crack that the sealant does not repair. They have a higher price than tubed tyres.

Recommended use: Tubeless tyres are a highly recommended alternative to classic tubular tyres and the range of brands is increasing rapidly.

1.3 Tubular

Tubular tyres consist of a tube cased in a cotton or silk mesh and this is cased in another layer with the tread. The three layers form a single compact body and this is fixed with a special glue or double-sided adhesive tape to the rim, which has a flatter contact surface and no lateral projections. This system was used on the first road bikes and has evolved, thanks to new materials and technologies.

Pros: It allows up to 11 bar tyre pressure, which prevents tyre deformation and ensures very low rolling resistance. It gives a more comfortable ride than other types of tyres at this pressure and is more resistant to punctures.

Cons: Laborious and time-consuming to fit, requiring hours of waiting for the adhesive to dry, even when initially fitted. The spare means packing the tubular tyre, which is bulky, as there is no inner tube, and it is complex to mount.

Recommended use: Mainly for competition.

1.4 Solid Airless Tyres

The Korean brand Tannus has filled a gap in the market with their airless road tyres.

Pros: It is the only system that offers total protection again punctures.

Cons: They offer a limited range of options and cannot be customised. They are time-consuming to fit and remove. They have not yet reached the performance of traditional tyres, although their constant evolution is bringing them closer.

Recommended use: Perfect for non-demanding activities, such as urban cycling and cycle touring, as they allow the rider to forget entirely about punctures. This type of tyre is certainly expected to become more popular in the future.

2. Width of Road Tyres

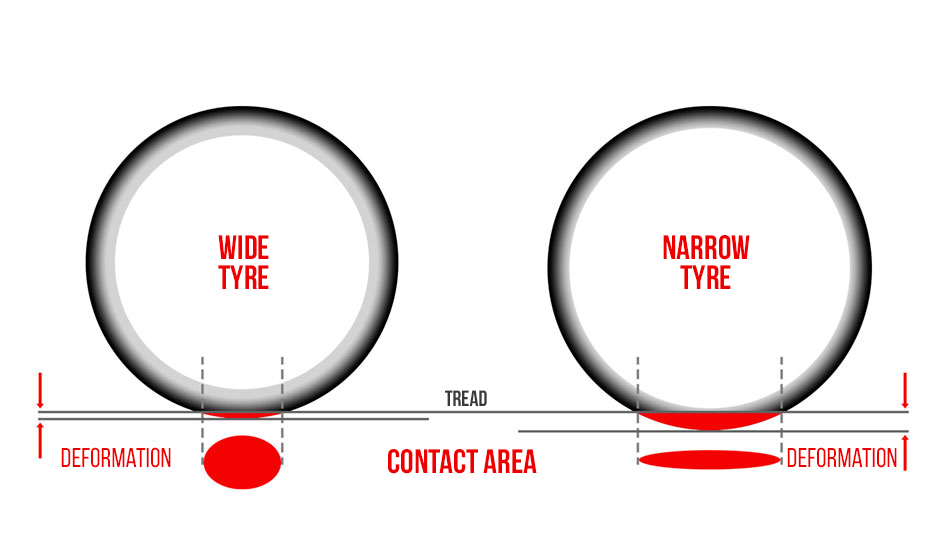

Numerous studies have concluded that, at the same pressure, a wider tyre leaves a wider but shorter footprint than a narrow tyre. This means the wider tyre deforms less and remains rounder. This can be seen in the graph below:

The smaller deformation of the wider tyre means it can be used with lower pressure, or with the same pressure for optimised performance.

Lower pressures increase grip, especially on bends and wet terrain, and increase ride comfort, due to greater flexing and absorption of ground irregularities.

The larger tyre volume also improves grip on bends, because the braking retention and lateral contact surface is larger when leaning. This is very convenient, especially with the expansion of disc brakes on the road, which are more powerful than rim brakes.

In short, wider tyres are faster, safer and more comfortable, although other factors such as weight and aerodynamics need to be taken into account. Based on all this, we can conclude that the appropriate width for climbing or speed bikes is between 24 and 26 mm and for long-distance bikes or when riding on regular or uneven roads, the ideal width is 28 mm.

3. Tyre composition

Other important factors that influence rolling resistance and tyre performance are: casing density, casing material and tread compound..

3.1 Casing Density TPI

The inner casing is manufactured with overlapping layers containing yarns and a compound that compacts the whole. The amount of yarns used defines the density and character of the casing and is measured by TPI (Threads Per Inch).

A higher TPI indicates that the casing is denser and contains more threads per inch and less compound or rubber. This results in a lighter, less deformable tyre with lower rolling resistance, but it is also more vulnerable to punctures and wear and more uncomfortable on uneven roads.

A low TPI indicates that thicker yarns have been used, with lower density and more compound. It will be a heavier tyre that gives more comfortable riding on poor road surfaces and, above all, more resistance to punctures.

The usual densities of road tyres are between 60 and 120 TPI, although some models reach up to 180 TPI by superimposing layers. Tubular tyres reach over 300 TPI, due to their cold vulcanised system that allows the use of finer threads. This very high density is what allows up to 11 bar pressure and provides the lowest rolling resistance coefficient of these tyres.

3.2 Tread Compound

The tread compound is crucial in defining the performance of the tyre. The most commonly used compounds are those derived from rubber, with added elements to improve their properties. The hardness is indicated by a number followed by the letter "a" and road tyres are usually between 60a and 70a.

The smaller the number, the softer the tyre and greater the grip, however they also wear out faster. A harder compound rolls better and delays wear, but loses grip.

Some tyres are made with double or triple compounds, depending on the zones. The harder compound is usually placed in the centre of the tread and the softer is used for the sides to improve performance on bends.

Softer tyres are usually used for competition or on surfaces that require greater grip. Harder tyres are suitable for daily use, for training or long distance riding.

3.3 Puncture Protection Reinforcements

All leading brands include anti-puncture systems in their tyres, either with bands inserted between the casing and the tread, or with reinforced compounds on all or part of the tyre surface. There are many names, so we will not list them here. In general, these protections increase the weight of the tyre and a balance is required, according to the use of the tyre.

Specialized Turbo Pro tyre with Blackbelt anti-puncture system

Specialized Turbo Pro tyre with Blackbelt anti-puncture system

3.4 Surface and Tread

The last factor we are going to analyse is the shape or relief of the tread.

Slicks: With a smooth surface, this tread offers the most grip in dry conditions and the least rolling resistance, and are also the most popular for racing and high performance. They have limitations on wet or uneven terrain, although these are reduced by using soft compounds.

Semi-slicks: These have a smooth central tread with relief on the sides, to improve grip on bends and on uneven terrain. They maintain very low weights and rolling resistance coefficients.

Treads: All-purpose, all-weather tyres, usually with lower TPI densities and hard compounds. In these tyres, reliability against punctures, grip on all types of road surfaces and durability are paramount, while sacrificing weight. They are most commonly used by sports and touring cyclists and by those who prioritise reliability and safety more than low weight. An example of this type of tyre is the best-selling Specialized All Condition Armadillo and its lighter version Armadillo Elite.

Specialized Tyres

Specialized Tyres

3.5 Tyre Pressure

Although tyre pressure, in itself, is not a tyre characteristic per se, we will take a brief look, as it can alter all the properties we have analysed, conditioning the tyre's behaviour.

In the section on tyre types and widths, we have already seen how increasing pressure reduces tyre deformation and, as a consequence, friction, making the tyre faster, but with less grip and less comfort. Lower pressure, on the other hand, increases grip and comfort, to the detriment of speed. This ability to modify tyre behaviour should be taken into account when choosing tyre pressure.

Typical tyre pressures on the road range from:

- 6 and 7 bar for lighter riders or tubeless tyres that allow lower pressures.

- 6.5 and 8.5 bar for tubed tyres, depending on the weight of the rider, the type of tyre and the road surface.

- 9-10 bar for tubular tyres, although in some cases up to 11 bar is possible.

The choice will depend on several factors such as rider weight, tyre width, road conditions, desired performance and rider preference.

It is usual to add 0.5 bar on the rear tyre, due to the greater weight it supports, and also to lower the pressures for wet or very uneven surfaces. But it is always advisable to respect the maximum and minimum limits recommended by the manufacturer and move between these to customise the pressure according to your needs.

We won’t go into further detail in this article, but these suggested ranges can serve as a starting point .

Specialized Air Tool UHP Floor Pump

Specialized Air Tool UHP Floor Pump

Summary and Recommendations

As we said at the beginning, the right choice seeks a balance between all these characteristics, according to your preferences and needs. Each cyclist chooses which of these qualities to prioritise, according to the intended use of the bike.

With the information we have given you and the wide range of tyres from top brands, available at mammothbikes.com you can easily choose the perfect tyres for your needs.

Image: © Specialized Bicycles

Image: © Specialized Bicycles

Specialized Turbo Pro tyre with Blackbelt anti-puncture system

Specialized Turbo Pro tyre with Blackbelt anti-puncture system

Specialized Tyres

Specialized Tyres

Specialized Air Tool UHP Floor Pump

Specialized Air Tool UHP Floor Pump

Leave a comment

Be the first to comment on this article.